We wanted a simple TV stand, something to get the TV at a height of 25" for easy viewing, and some storage space for DVDs, the cable and BluRay boxes, and maybe a blanket.

The other interesting part of this project, is that it is the first project I am finishing with all water based finishes. I purchased water based shellac and lacquer for this project, and will spray the finish with my new Earlex HVLP spray setup.

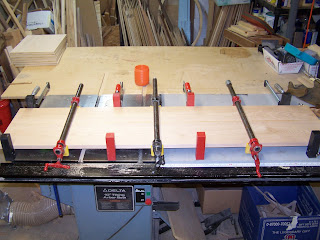

Here are some pictures of the project:

The side panels and doors are constructed with 1/4" panels, as opposed to the 3/4" raised panels I usually build with. Using my bandsaw, I was able to cut the panels and arrange the grain in a bookmatched manner, which I believe adds to the visual appeal of the finished product.

There are accomodations for more than one shelf behind each door, but for now, one shelf seems to do the job just fine.

There's ample room for components in the center area.

There's ample room for components in the center area. Look at that grain pattern; I have to say, it didn't take much skill to build a beautiful piece of furniture when the grain does all the hard work!

Look at that grain pattern; I have to say, it didn't take much skill to build a beautiful piece of furniture when the grain does all the hard work!